High-Resolution Concrete Panels with Additive Formwork

ABOUT THE PROJECT

The project High-Resolution Concrete Panels with Additive Formwork seeks to untap the full potential of concrete by exploring a novel approach to formwork manufacturing. Through the combination of computational design logics and the flexibility of Additive Manufacturing, this experimental work exploits unreached levels of customization for the most used material in constructions.

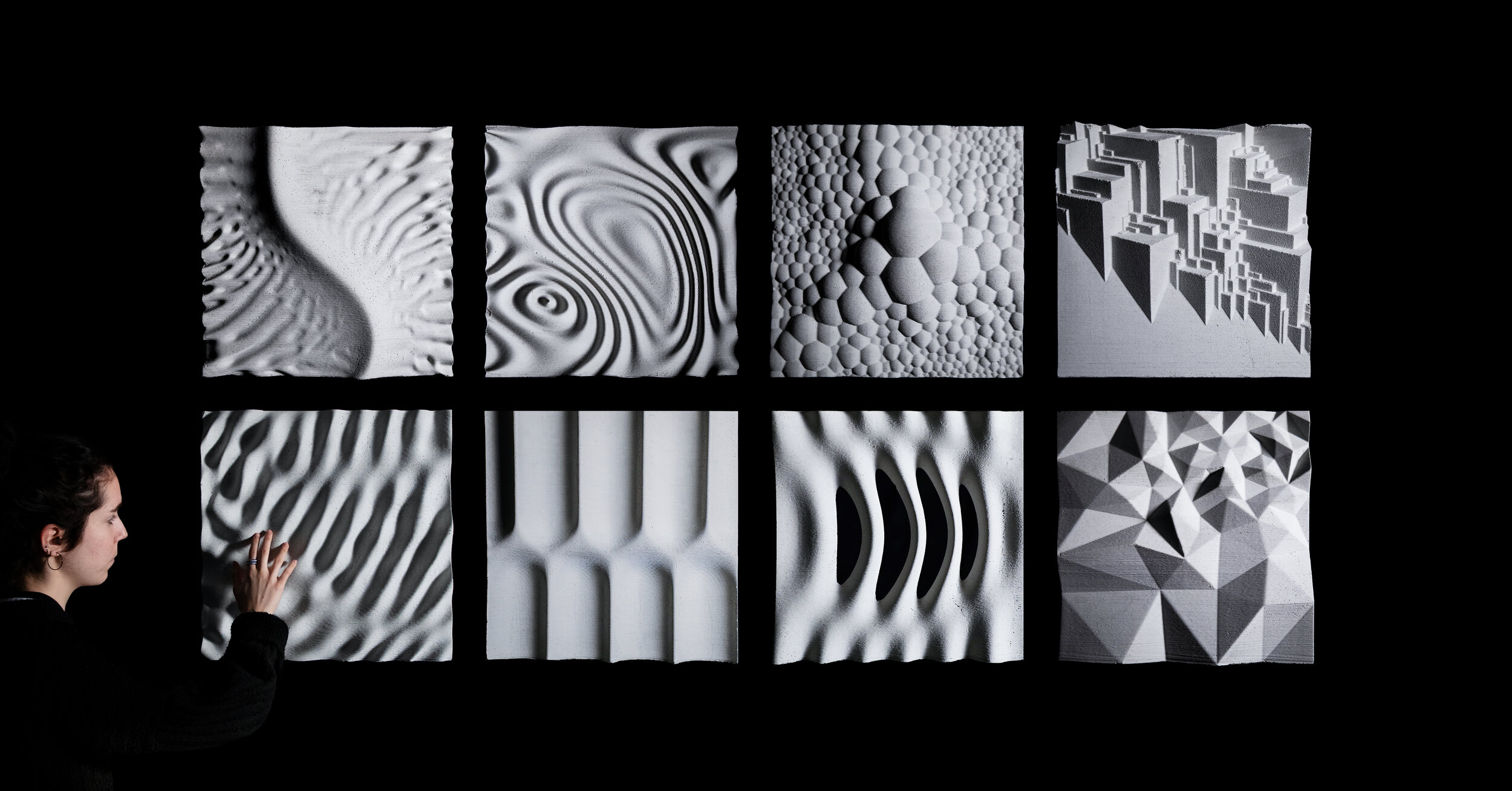

The lack of detail in existing formworking confines concrete architecture to passively inherit the features of moulding materials such as wood. This work utilizes computational processes to actively characterize a further design dimension, the one of texturing, which is informed by performative and morphological features. The process finds analogies in nature, where textures provide a level of functional specification and information regarding an organism’s development, as well as in the arts, where textures are an effective dimension of a composition, necessary to convey a message by simultaneously stimulating the senses of sight and touch.

To celebrate the possibilities offered by the union of high-resolution 3D Printing and the material properties of Ultra High-Performance Fiber Reinforced Concrete (UHPFRC), a set of concrete panels with unique design was realized, following distinct computational processes ranging from natural to abstract inspirations: from the organic shapes generated by reaction-diffusion logics, sphere packing, sand wave patterns, to polygonal assemblies that resemble mineral formations, meshed surfaces, and topological discontinuity.

The fabrication process involves the use of large scale Fused Deposition Modelling (FDM) and upcycled plastic waste to shape additively formworks that have highly unique morphological features: multi-scale curvature, variable sections, topological discontinuity, sharp/smooth edges. High-precision 3D scanning has been utilized to evaluate the precision and repeatability, with average deviations smaller than 2 millimeters.

Ultimately, the project demonstrates the unique possibilities of producing high-resolution and high-precision concrete panels for indoor and outdoor applications, with the use of reusable formwork made of upcycled plastic material.

PROJECT CREDITS

CREATE Group - Led by Asst. Prof. Dr. Roberto Naboni

University of Southern Denmark (SDU), Section for Civil and Architectural Engineering (CAE)

Team: Roberto Naboni, Luca Breseghello, David W. Jokszies

3D Scanning: at the SDU Prototyping Lab (Prof. Knud Bjørnholt)

Industry Partners: WASP (3D Printers), Hi-Con (High-Performance Concrete)